Technology

Wire Arc Additive Manufacturing (WAAM) is an advanced 3D metal printing process that uses an electric arc to melt metal wire, layer by layer, to build near-net-shape metal parts. It combines the strength of welding with the precision of additive manufacturing, making it ideal for producing large, strong, and cost-efficient metal components.

Our specialization in WAAM is a game-changer in the industry as it seamlessly combines real-time parameter monitoring with the intricate manufacturing process of 3D metal parts. We shape this technology by utilizing either TIG or MIG welding-based on specific project needs, to implement WAAM with advanced automation. By closely controlling key process parameters and adhering to top industry standards, Alloy Additive ensures maximum efficiency in both manufacturing and repairing metal parts.

WAAM Hardware and Setup

Power Source

A welding power supply (MIG, TIG, or Plasma) provides the electric arc needed to melt the metal wire.

Motion System

A robotic arm controls the movement of the torch or the workpiece for accurate layer deposition.

Control Software

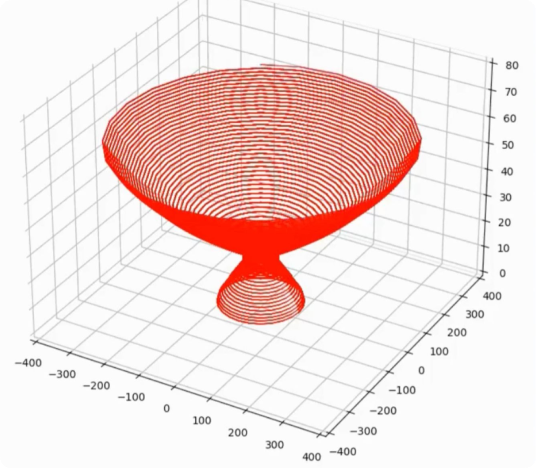

Software converts CAD files into toolpaths and coordinates all hardware elements (motion, wire feed, arc control).

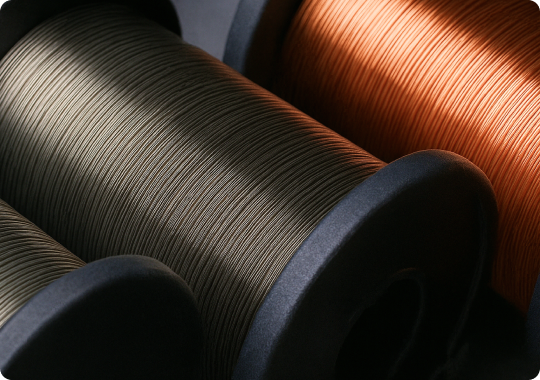

Wire Feed System

A motorized feeder delivers metal wire (usually on a spool) at a controlled rate to the welding torch.

Build Platform

A base plate (often preheated) supports the part during printing and ensures good adhesion for the first layer.

Cooling System

Fans or water-cooling systems help manage heat and reduce thermal distortion during the build.

Power Source

A welding power supply (MIG, TIG, or Plasma) provides the electric arc needed to melt the metal wire.

Motion System

A robotic arm or multi-axis CNC gantry controls the movement of the torch or the workpiece for accurate layer deposition.

Control Software

Software converts CAD files into toolpaths and coordinates all hardware elements (motion, wire feed, arc control).

Wire Feed System

A motorized feeder delivers metal wire (usually on a spool) at a controlled rate to the welding torch.

Build Platform

A base plate (often preheated) supports the part during printing and ensures good adhesion for the first layer.

Cooling System

Fans or water-cooling systems help manage heat and reduce thermal distortion during the build.

Automation & Optimization

Robotic arms follow programmed toolpaths to move the torch precisely, reducing human error and ensuring repeatability. Sensors (e.g., for temperature, arc stability, wire feed rate) monitor the build in real time to detect issues like defects or misalignment. Software algorithms optimize deposition paths, layer thickness, and welding parameters to reduce material use, energy consumption, and build time. These features make WAAM not only scalable for large parts but also efficient, consistent, and cost-effective.

THD® (Tungsten High Deposition)

Discover the revolutionary potential of Alloy Additive’s Patented WAAM technology, THD® (Tungsten High Deposition), a game-changer in additive manufacturing. With an impressively high deposition rate for printing titanium, our advanced TIG system dramatically enhances production efficiency for large and complex metal parts. Paired with our in-house developed 3D printing software, we guarantee precise control and optimization throughout the fabrication process, ensuring consistent quality for every /specific requirements for strength and durability, setting us apart in the industry. The versatile setup of our THD® technology adapts seamlessly to a variety of applications, making it the ideal solution for diverse manufacturing needs. Unlock the unparalleled capabilities of THD® with Alloy Additive and elevate your projects in the world of metal additive manufacturing today!

Process flow

1. Design Submission

You provide a 3D CAD model of the part you need. Our engineers review it for manufacturability using WAAM.

2. Path Planning & Process Setup

We convert your CAD file into a digital toolpath, defining how each metal layer will be deposited. The system is configured for the selected metal wire (e.g., titanium, stainless steel).

3. Layer-by-Layer Deposition

The robotic arm precisely deposits the molten metal in layers, following the toolpath to build the part shape.

4. Controlled Coolingn

Each layer cools and solidifies before the next one is added to ensure structural integrity and minimize distortion.

5. Post-Processing

Once the build is complete, the part may undergo machining, heat treatment, or surface finishing to meet your specifications.

6. Inspection & Delivery

The final part is inspected for quality and dimensional accuracy, then delivered ready for use or further integration.

Materials

As an innovative metal additive manufacturing company, Alloy Additive specializes in producing high-performance alloy components from a comprehensive materials portfolio. These advanced alloys meet the stringent requirements of aerospace, energy, and oil-gas industries through rapid solidification during the printing process, resulting in refined grain microstructures that deliver exceptional strength and elongation properties

Titanium

Nickel

Steel

Copper

- Ti-6Al-4V

- Ti1100

- Ti6422

- Inconel 718

- Inconel 625

- SS 316L

- SS 422

- Duplex SS

- SS 15-5 PH

- SS 17-4 PH

- SS 13-8 Mo

- CuSn6P

- CuSn12P

- CuAl8

Want the details? Set up a quick demo.

Fill in the form, explain your need, even provide .STEP file for us to analyze the problem and provide solutions and offers.