From exotic alloys to extreme geometries manufacturing, reprogrammed.

Technology

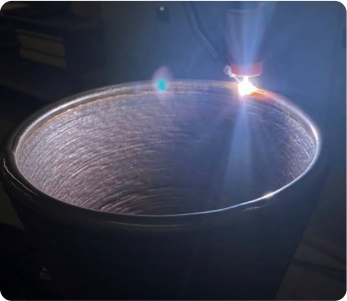

Our specialization in WAAM is a game-changer in the industry as it seamlessly combines real-time parameter monitoring with the intricate manufacturing process of 3D large and complex metal part printing.

Hardware and Setup

We engineer and leverage robust, scalable WAAM systems tailored for industrial environments-integrating multi-axis robotic arms, advanced arc welding technology, and proprietary control software for precision and repeatability.

Materials

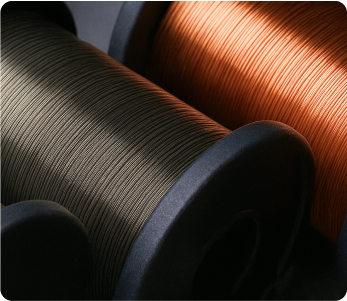

Our process is optimized for high-performance metals and alloys including titanium, nickel, Inconel, Invar, and other exotic materials-leveraging deep metallurgical expertise to meet the most demanding applications.

Exotic metal manufacturing without the wait high-strength parts Produced quickly, accurately, and cost-effectively

On-Demand Printing

The most significant innovation in Wire Arc Additive Manufacturing (WAAM) technology is its ability to utilize welding for complete part fabrication rather than just material joining. Alloy Additive’s WAAM process begins with design files that are sliced using specialized software, then printed layer by layer through controlled material deposition. This advanced additive manufacturing technique systematically transforms raw materials into fully functional 3D components, revolutionizing traditional manufacturing approaches.

Case Studies

Value propositions:

- Intersecting geometry

- Super Alloy 3D printing

- Fast delivery in hours instead of months

- Reduced material waste

Value propositions:

- Space flight proven

- 40% lighter than steel

- 60% lower cost

- Lead time 7 days instead of 7 weeks

Value propositions:

- Part upgraded for increased resilience for high temperature

- Extended life span

- Reduced downtime

- Reduced material waste

Want the details? Set up a quick demo.

Fill in the form, explain your need, even provide .STEP file for us to analyze the problem and provide solutions and offers.