Industries and Previous Projects

Aerospace

Unlike traditional methods, Alloy Additive’s WAAM technology offers a transformative solution that not only enhances efficiency but also aligns with the dynamic requirements of the space sector. You can find our previous products and projects below.

- Delta V – Aerospace

- Our 3D printed part titanium rocket nozzle extension was flown in a successful space flight.

- 40% lighter than steel, 60% lower cost, production in 7 days instead of 7 week, space flight proven

- Undisclosed Client (Turkey) – Aerospace

- Intersection geometry, Production in hours instead of months, supper alloy 3d printing, metal waste reduction

Turkish Aerospace Industries – Aerospace

Alloy Additive partnered with the leading aerospace company in Turkey, delivering premium engineering services that slashed lead times from circa 3 months to just 1 day. Our advanced solutions accelerated R&D workflows and unlocked greater design flexibility – creating substantial added value throughout the development process.

Penetrant Test OK, Dynamic Vacuum Leakage Test (180° C, 7 bars, 8 Hours)

Oil & Gas

For SOCAR and other energy partners, we’ve developed corrosion-resistant wellhead components that withstand sour gas environments, doubling service intervals.

- Part upgraded for resistance to high temperature conditions, successfully resulting in extended lifespan, reduced downtime and material waste.

- Impeller reproduced from the original version by using 3D scanning. New part upgraded for resistance to corrosion, successfully resulting in extended lifespan (with higher density ratio), reduced downtime and material waste.

Marine

Our advanced WAAM technology delivers innovative solutions for the marine and heavy equipment industries. We successfully produced a high-precision titanium component for a marine client in Spain, achieving up to 34% weight reduction for a hydrofoil sailboat racing component. Our 3D metal printing offers exceptional design flexibility, metal waste reduction, and lightweight materials that revolutionize marine component manufacturing.

- Undisclosed Client (Spain) – Marine

- Powered by our engineering expertise, Alloy Additive successfully delivered the complex, high-precision titanium component using our advanced WAAM technology.

- Design flexibility, Metal waste reduction, lightweight material

Heavy Machinery

Bucket teeth and wear plates reinforced with our carbide-enhanced WAAM deposits demonstrate 5-7x longer lifespan in quarrying applications.

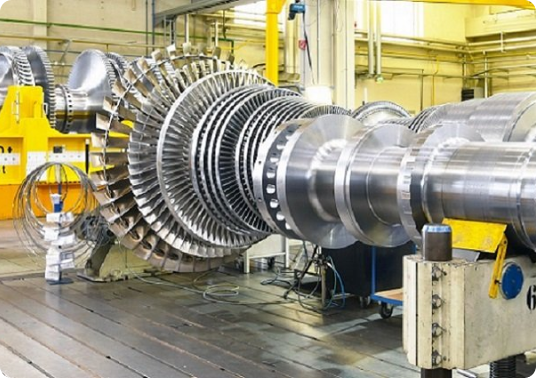

- Alstom – Heavy Machinery

- No Casting or molding, production in 24 hours instead of 3 months, design flexibility, no stock problem

- Alstom – Heavy Machinery

- Alloy Additive delivered transformative value to Alstom – acting as both a digital warehouse and a trusted engineering partner – achieving up to 90% cost savings and dramatically shortening lead times across multiple applications.

Want the details? Set up a quick demo.

Fill in the form, explain your need, even provide .STEP file for us to analyze the problem and provide solutions and offers.