Services

We’ve structured our offerings to address the full industrial lifecycle:

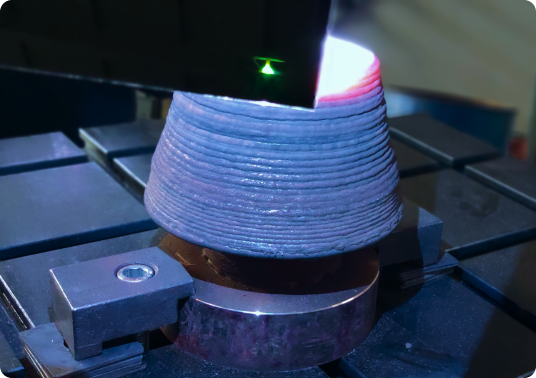

on-demand Printing

Alloy Additive delivers on-demand custom titanium, nickel and stainless steel parts in days using TIG-Wire Arc 3D printing. On-demand production eliminates supply chain delays and reduces costly equipment downtime with rapid replacement parts and custom components.

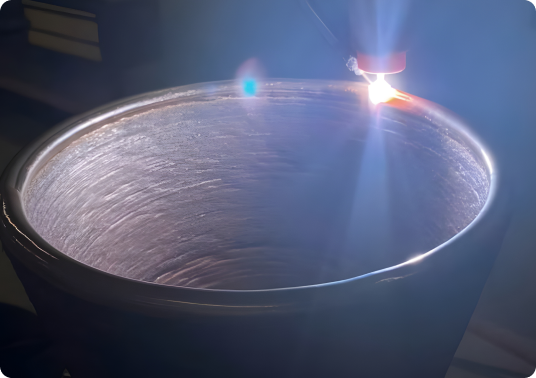

Part Repair Services

In leading industrial sectors, repair and refurbishment provide significant cost advantages for high-value components that experience damage or wear during their operational service life. Repairing metallic parts extends component lifespan while reducing material waste and energy consumption in manufacturing processes, delivering sustainable and economically viable maintenance solutions.

Reverse Engineering & Digital Inventory

Recover lost designs through high-resolution 3D scanning, then store certified CAD models in our secure vault for on-demand production – eliminating physical inventory costs.

Full-Scale Production

The biggest breakthrough in WAAM technology is using welding to build complete parts, not just join them together. Alloy Additive’s WAAM process starts with design files that are sliced by software, then printed layer by layer to create finished 3D parts. From single prototypes to full production runs, our WAAM systems produce aerospace-quality components using:

- Ti-6Al-4V – lightweight material for aerospace parts

- Inconel® 718 – heat-resistant alloy for extreme temperatures

- Martensitic stainless steel – strong material for tools and dies

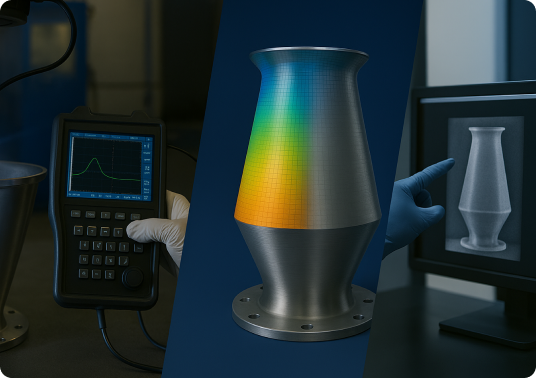

Quality Assurance

We test our final products to ensure it abides by industry specifications.

- In-process monitoring (arc stability, layer alignment)

- Non-destructive examination (X-ray, ultrasonic)

- Mechanical testing (tensile, fatigue)

- Final inspection report with traceable data

Value Proposition

Cost Efficiency

WAAM significantly reduces material waste compared to subtractive methods, especially for expensive metals like titanium, leading to lower overall cost.

Large-Scale Part Capability

WAAM can produce large, structurally sound metal parts that are difficult or costly to manufacture using traditional methods.

Design Flexibility

Complex or custom geometries can be produced directly from CAD files without additional tooling, enabling rapid iteration and customization.

Reduced Lead Time

Rapid prototyping to full‑scale production, enabling days‑not‑weeks delivery. Byeliminating the need for tooling and speeding up deposition, WAAM allows for faster turnaround from design to final part.

Sustainability

Less material waste and energy use contribute to a more sustainable production process – especially important in industries with environmental goals.

High Material Utilization

Wire feedstock has nearly 100% material use, maximizing efficiency and simplifying handling compared to powders.

Cost Efficiency

WAAM significantly reduces material waste compared to subtractive methods, especially for expensive metals like titanium, leading to lower overall cost.

Large-Scale Part Capability

WAAM can produce large, structurally sound metal parts that are difficult or costly to manufacture using traditional methods.

Design Flexibility

Complex or custom geometries can be produced directly from CAD files without additional tooling, enabling rapid iteration and customization.

Shorter Lead Times

Rapid prototyping to full‑scale production, enabling days‑not‑weeks delivery. By eliminating the need for tooling and speeding up deposition, WAAM allows for faster turnaround from design to final part.

Sustainability

Less material waste and energy use contribute to a more sustainable production process – especially important in industries with environmental goals.

High Material Utilization

Wire feedstock has nearly 100% material use, maximizing efficiency and simplifying handling compared to powders.

Case studies

Client: Alstom

Value propositions:

- Part repairment application

- Shortened lead times

- 90% cost savings

Client: Alstom

Value propositions:

- Mold manufacturing for aerospace grade composites

- Successfully passed penetrant and Dynamic Vacuum Leakage Tests

- Delivery time 3 days instead of 3 months

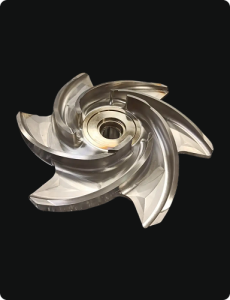

Client: SOCAR

Value propositions:

- Reverse engineering from the original part

- Part upgraded for resistance to corrosion

- Extended lifespan and high density (increased strength)

- Reduced downtime

- Reduced material waste

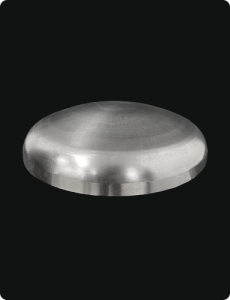

Client: Delta V

Value propositions:

- Space flight proven

- 40% lighter than steel

- 60% lower cost

- Lead time 7 days instead of 7 weeks

Client:Undisclosed Turkish Company

Value propositions:

- Intersecting geometry

- Super Alloy 3D printing

- Fast delivery in hours instead of months

- Reduced material waste

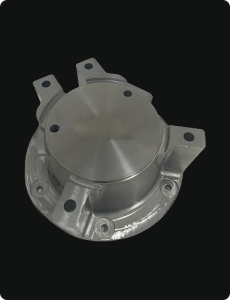

Client: SOCAR

Value propositions:

- Part upgraded for increased resilience for high temperature

- Extended life span

- Reduced downtime

- Reduced material waste

Client: Alstom

Delivery time: 24 hours instead of 3 months

Value propositions:

- Digital Warehouse

- No casting or mold costs

- Design Flexibility

- No stock problem

Want the details? Set up a quick demo.

Fill in the form, explain your need, even provide .STEP file for us to analyze the problem and provide solutions and offers.